AEROSPACE

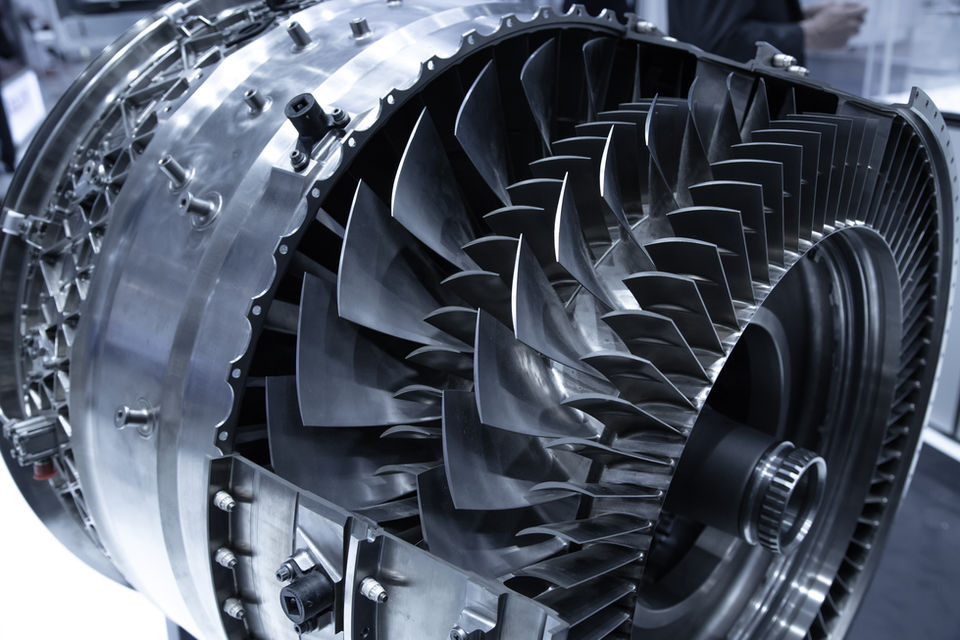

Next-generation materials and manufacturing for reliable and repeatable parts production & sustainment

The next 30 Years of aerospace will be defined by three enabling technology areas: (1) Connectivity, (2) Novel Materials & Manufacturing, and (3) Automation. These three themes are driving new and alternative modes of thinking about aerospace including air taxis, supersonic flight, delivery drones, low-cost satellite launches, new space vehicles, reusable rockets, and many more.

At the core of these use cases are a desire to travel further, faster, and with fewer hassles. Consumers are looking for increased stability in prices and a reduced carbon footprint. Businesses are looking for faster and more secure movement of goods. Finally, governments are looking to maintain stringent safety requirements while continuing to support climate-friendly initiatives.

Aerospace manufacturing can’t depend on a single manufacturing process or region to achieve necessary performance targets.

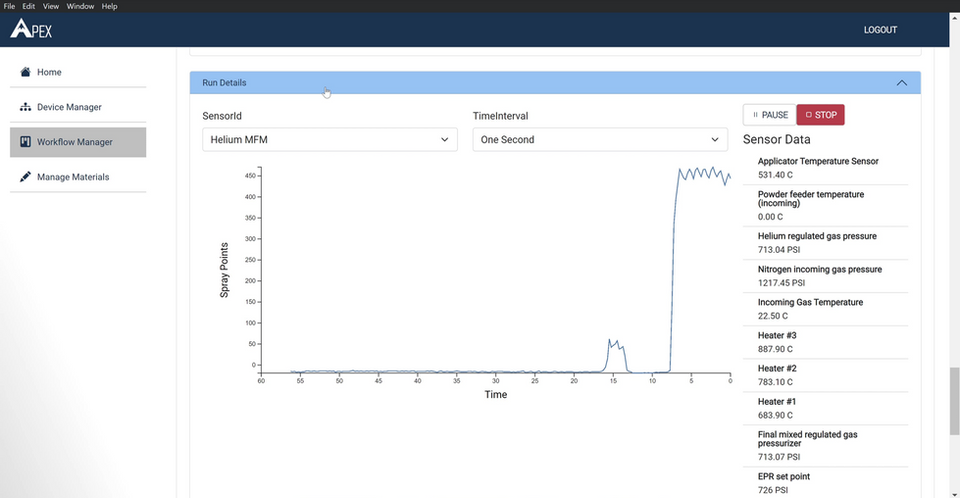

The future of manufacturing for aerospace depends on the ability to fabricate high-strength, elevated temperature structures, near the point of assembly to minimize supply chain costs and ensure rapid delivery. This requires highly controlled, qualified additive manufacturing solutions that can handle a range of high-performance materials. Further, it may require multiple AM and coating techniques be used in concert to achieve the best possible performance properties.

During fabrication, these parts will need to be held to the highest quality assurance and security standards, ensuring that raw materials as well as parts are tightly controlled and certified physically as well as digitally. As the industry continues to think about its future sustainability and climate impact, more metal consumers are looking to secondary and recycled alloys to provide low-cost, high-performance options.

A robust and secure physical and digital supply chain is needed to ensure industry success.

New power architectures will enable next generation designs and applications

As electrification of the aerospace industry continues to transform the size, scale, and quantity of energy storage methods used, there is a growing need for more energy dense, safe, and configurable batteries that can readily be adapted into pack-level solutions for novel aero-architectures.